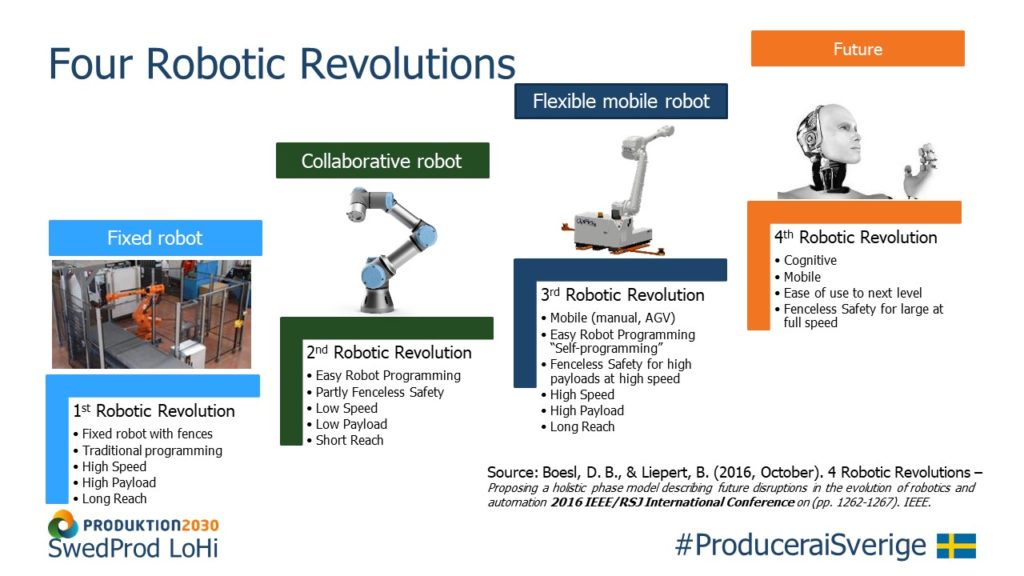

The challenges of automating small series production as well as high mix and low volume are driving robot development towards demands for higher flexibility where completely new robot generations have been developed. We are beginning to enter the third robot revolution with flexible robots. These are the four robot revolutions.

There is an article on edig which is a knowledge platform with the aim of raising the digitization competence in the industry about the four robot revolutions. The article is here

The trends “increased global competition” and “high mix and low volume” drive sharply increased automation in general and in particular flexible and future-proof automation. The background is that customers want greater freedom of choice of product configurations, shorter product lifetimes and higher competition.

New technology opens up new possibilities for flexible automation, an example is OpiFlex flexible mobile robot cell with simple programming and safety solution without a fence, see video below

There are four robot revolutions defined and the different robot types are suitable for different types of needs, see picture below.

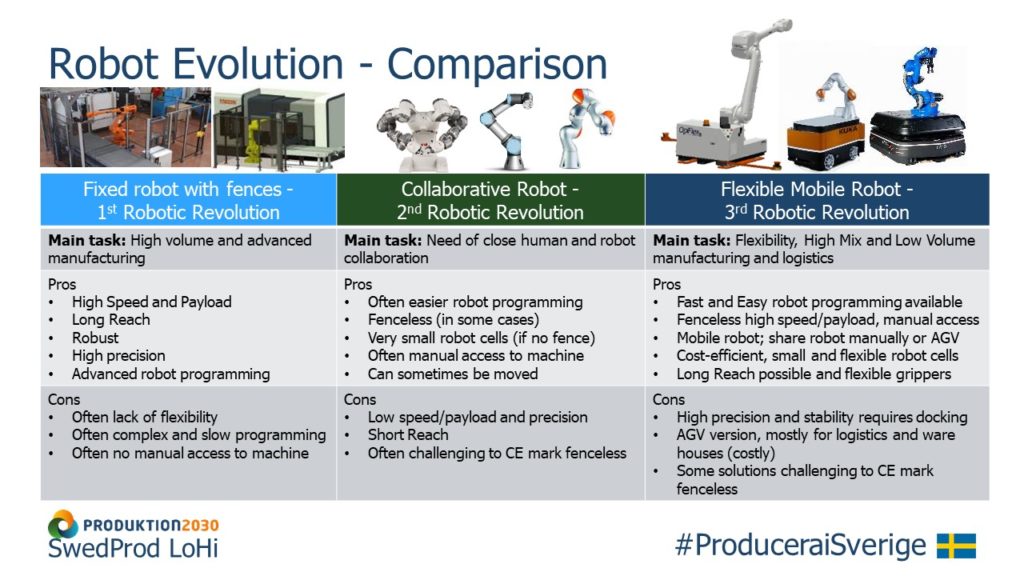

- The first robot revolution “Fixed robots” – traditional robot solutions with fixed robot, fence and traditional robot programming. Has been used mostly for high volume production with few variants. These robot solutions take time to install and can sometimes take up a lot of space due to fences. Programming is done by writing code in the current robot supplier’s language, normally 3,000–4,000 lines of code. It often takes time to change programs for a new article, as the code must be changed. However, there are some solutions where certain parameters can be changed to create simpler programming. There are some solutions that allow manual access, but it can be difficult to get a flexible solution for high mix and low volume. Examples of manufacturers: All robot manufacturers

- Second robot revolution “Collaborative robots” – new type of robots that are easier to use, can be used in part without fences and go slowly and stop when someone accesses them. It can be difficult to comply with ISO / TS 15066: 2016, which specifies safety requirements for collaborative industrial robot systems and applications, without additional safety solutions such as fences, laser curtains or laser scanners. It is about 4% of the applications according to studies where robot and human need to actively cooperate. Programming is often simpler than for traditional robots, but still requires all the logic and interconnection of the machine or equipment to function. These are intended to be used primarily where humans and robots need to work together. Examples of manufacturers: Universal Robots (UR3, UR5, UR10), KUKA (LBR iiwa); ABB (Yumi), Yaskawa (HC10, SDA, SIA), Doosan et al. This area has very strong growth and is popular with the right applications, but many realize disadvantages as they are slow, have a shorter range and handle relatively low loads. It is also difficult to maintain safety requirements and to CE mark.

- The third robot revolution “Flexible robots” – large mobile robots without fences that meet the safety requirements at high speed and high load and simple robot programming on a new level, with a new type of flexibility. They can be moved manually or automatically and can be run at full speed without a fence, which means that they can be used on one machine or easily shared with several machines and provide full manual access to the machine. They have a simple robot programming where the robot already knows how the machine and the robot cell work. The robot creates the program itself by the operator showing the order in which it wants to operate the machines / stations, answering a few simple questions and showing, for example, how to grab an object or put it in the machine. Examples of manufacturers: OpiFlex (MRP10, MRP20, MRP60 with small / large ABB robot with manual or AGV pallet truck movement), MIR (AGV with cobot), Omron (AGV with cobot) (AGV with cobot), Kuka (AGV with cobot or large robot). Very strong growth and demand from both smaller companies, but also large OEMs and TIs1 as they can handle both high flexibility, high performance and thus a future-proof solution. They also meet all safety requirements for CE marking without fences.

- The fourth robot revolution “Thinking robots” – The idea is to be able to create thinking robots with AI and grippers that look like fingers, this in combination with large mobile robots without fences that meet the safety requirements at high speed and high load. It is attractive but difficult as a lot of data is usually needed to learn and especially in short series. There are examples of grippers from, for example, Schunk that look like fingers, but these are prototypes that lift a little and are expensive. Sees this as a future yet, but clearly interesting.

If you want to read more about possibilities with flexible robot solutions and how they can be used, read more here

Customer examples of the use of flexible robots can be found here